|

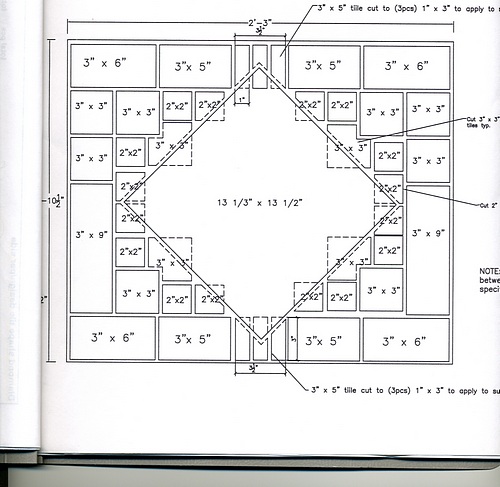

The tile lay out for side one.

Click to see details.

The poor old fountain had fallen into a dilapidated state. So ugly, the decision was made to remove it. However, being

built of steel from the ship yards it proved to be indestructable. After three cuts had been made with a giant diamond saw

the contractor decided it was too diffucult and gave up! It looked as if the once grand old fountain was to be given

a possible reprieve. You can see these cuts if you click on the pictures. This is where KD came in! We welded the cuts back

up, cleaned it, made it fount again, made it empty into its downstream counterpart (instead of under the house!) and

concreted its knarly steel sides smooth.

The inside border being installed, propped up with wood.

The square motive on the alternate sides. These sides were easier because the four central tiles were the same thickness

as the other tiles.

The original marble footings of the old fountain were cleaned up and reinstalled. The narrow base at the foot of the

fountain was designed to echo the edgeing of the flower beds (yet to be planted).

We were unable to locate the material called Gunnite for the center of the fountain so we used "Zypex" to waterproof

the concrete on the inside of the fountain. When this had hardened we painted it a turquoisy blue, to match some of the tiles

and a staircase which is visible from this courtyard.

Remember, this is how it started out. Imagine what a new one would have cost, and it is doubtful that a new one would

have lasted one hundred years - as this old one did.

|